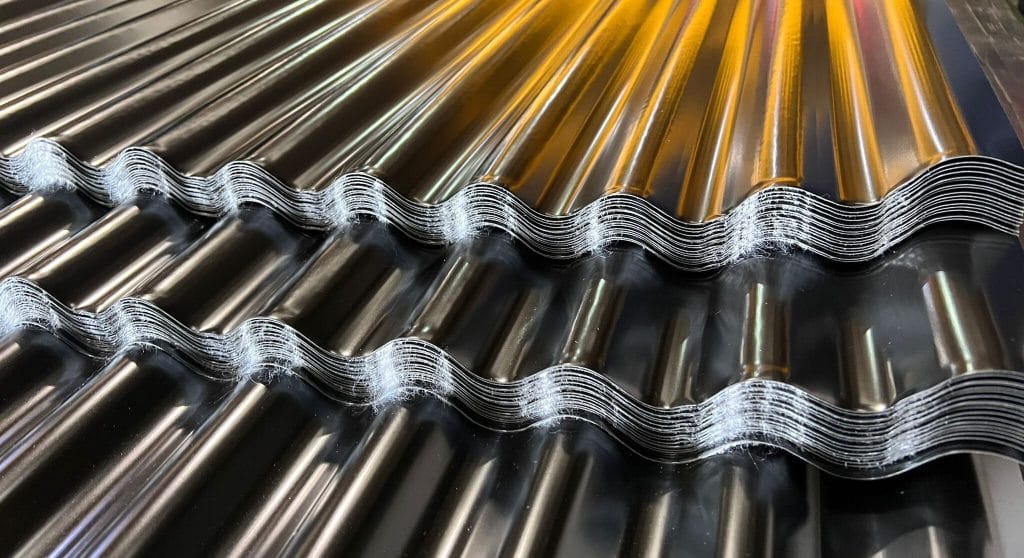

What is Corrugated Steel (Profiling Sheet)?

Corrugated steel, also known as profiled steel sheet or “profnostil,” is a lightweight, durable, and cost-effective material made by cold-rolling galvanized steel into a wave-like or trapezoidal profile. This profiling adds strength, rigidity, and load-bearing capacity to the sheet, making it an excellent choice for various construction applications.

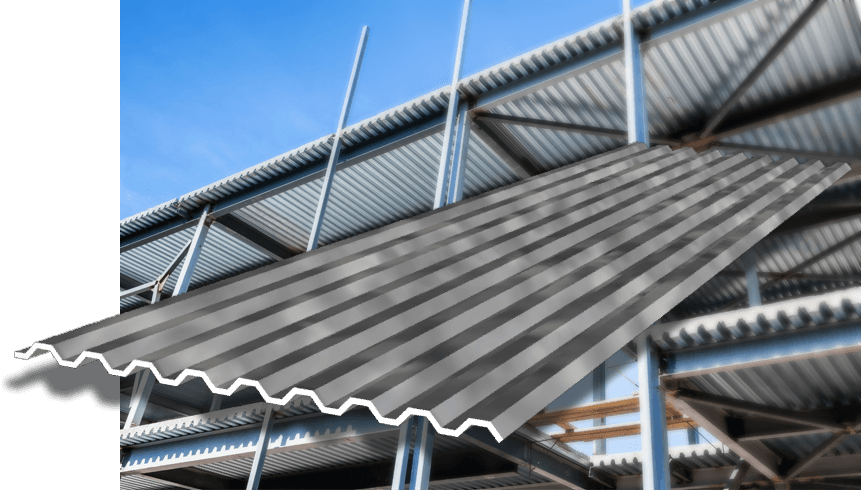

In frame house construction, corrugated steel is widely used for roofing, cladding, fencing, and structural components. Its versatility, ease of installation, and long lifespan make it a preferred material for builders seeking efficiency and durability.

History and Origin of Corrugated Steel

The use of corrugated metal dates back to the early 19th century. It was first patented in the 1820s by Henry Robinson Palmer in Britain, who developed the process of corrugating thin metal sheets to enhance their strength. Initially made from wrought iron, corrugated metal gained widespread popularity in the late 19th century with the advent of galvanized steel.

Today, advancements in coatings and manufacturing techniques have made corrugated steel one of the most reliable and versatile materials in modern construction.

Applications in Frame House Construction

Corrugated steel is used in various parts of frame houses due to its strength, weather resistance, and adaptability. Common applications include:

• Roofing: Corrugated steel sheets are widely used for roofs in residential and commercial buildings due to their durability and water resistance.

• Facade Cladding: Corrugated steel provides a modern, industrial aesthetic while protecting walls from weather conditions.

• Fencing: Durable and low-maintenance, corrugated steel sheets are used for perimeter fencing and boundary walls.

• Structural Support: In some cases, corrugated steel sheets are used as load-bearing elements in walls and floors.

• Ceilings and Decorative Elements: The material can also be used indoors to create an industrial or rustic aesthetic.

Leading Manufacturers of Corrugated Steel

Several companies are known for producing high-quality corrugated steel sheets, trusted by builders and architects worldwide. Leading manufacturers include:

1. ArcelorMittal (Luxembourg): One of the largest steel producers globally, offering durable and customizable corrugated steel solutions.

2. BlueScope Steel (Australia): Known for their COLORBOND® and ZINCALUME® products, widely used for roofing and cladding.

3. Nucor Corporation (USA): A leading U.S. manufacturer of steel products, including corrugated steel for construction.

4. Tata Steel (India): Offers a wide range of corrugated sheets with advanced coatings for extended durability.

5. Ruukki (Finland): Specializes in premium corrugated steel solutions with excellent corrosion resistance and aesthetics.

These manufacturers provide a variety of profiles, thicknesses, and coatings to meet the demands of different construction projects.

Costs and Economic Feasibility

Corrugated steel is one of the most cost-effective materials for frame house construction. The price varies depending on the thickness, profile type, and coating. In the U.S., average prices are:

• Standard Corrugated Steel Sheets: $1.50–$3.50 per square foot.

• Premium Coated or Painted Sheets: $3.00–$5.50 per square foot.

Corrugated steel is not only affordable upfront but also offers long-term savings due to its low maintenance requirements and extended lifespan. Its fast installation further reduces labor costs.

Advantages of Corrugated Steel

1. Durability: Corrugated steel is highly resistant to mechanical damage, weather, and corrosion when properly coated.

2. Lightweight: Its light weight reduces the load on the frame and foundation, making it ideal for frame houses.

3. Ease of Installation: Corrugated steel sheets are easy to handle, cut, and install, saving time during construction.

4. Weather Resistance: Galvanized and coated sheets provide excellent protection against rain, snow, and UV exposure.

5. Cost-Effective: Corrugated steel offers one of the best cost-to-performance ratios among construction materials.

6. Fire Resistance: Steel is non-combustible, contributing to the fire safety of the structure.

7. Aesthetic Versatility: Available in various profiles, colors, and finishes, corrugated steel can complement both modern and traditional architectural designs.

Disadvantages of Corrugated Steel

1. Thermal Conductivity: Steel can transfer heat and cold, requiring proper insulation when used in roofs or walls.

2. Noise Levels: Rain or hail hitting a corrugated steel roof can produce significant noise, necessitating soundproofing solutions.

3. Corrosion Risk: While galvanized or coated steel resists corrosion, scratches or improper maintenance can lead to rust over time.

4. Limited Design Flexibility: Corrugated steel’s rigid structure can be less suitable for complex architectural designs.

5. Potential Denting: Thinner sheets may dent under heavy impact, requiring careful handling during installation.

Conclusion

Corrugated steel is a practical, durable, and cost-effective material widely used in frame house construction. Its versatility in applications, from roofing and cladding to structural support, makes it a valuable addition to any project.

While it has some limitations, such as thermal conductivity and noise, these issues can be addressed with proper insulation and soundproofing. The affordability, durability, and aesthetic flexibility of corrugated steel ensure its continued popularity in modern construction, making it an excellent choice for builders and homeowners alike.