What is Drywall?

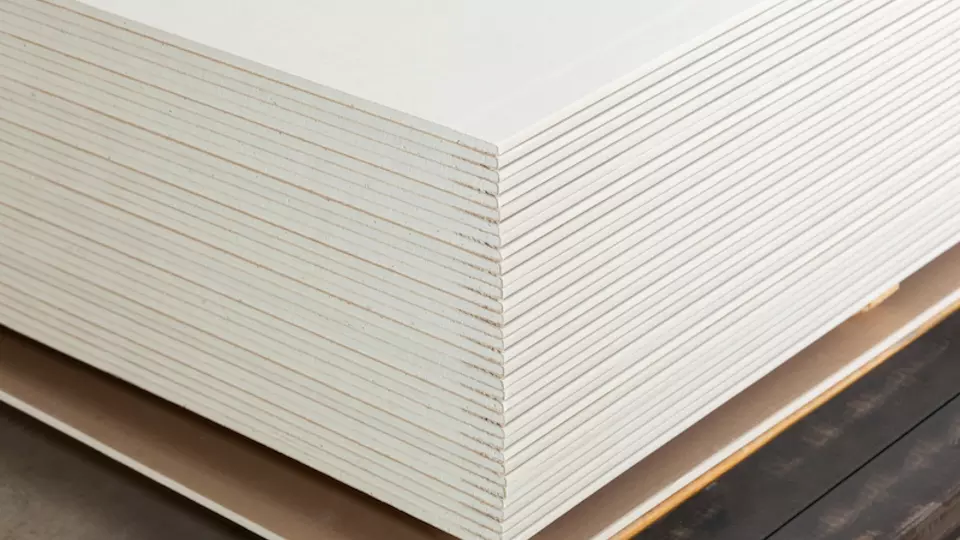

Drywall, also known as gypsum board, plasterboard, or sheetrock, is a building material composed of a gypsum core sandwiched between sheets of heavy paper or fiberglass. It is widely used for creating walls and ceilings in residential and commercial construction.

In frame house construction, drywall is the primary material for interior finishes due to its affordability, ease of installation, and versatility. It provides a smooth surface for painting or wallpapering and contributes to the thermal and acoustic performance of a structure.

History and Origin of Drywall

Drywall was invented in 1916 by the United States Gypsum Company (USG) as a quicker and more efficient alternative to traditional plaster walls. Initially marketed as “Sackett Board,” it evolved into modern gypsum board, becoming a staple in construction during the mid-20th century due to its speed of installation and cost-effectiveness.

Today, drywall is the most commonly used material for interior walls and ceilings in the construction industry, with innovations such as moisture-resistant and fire-resistant varieties enhancing its performance.

Applications in Frame House Construction

Drywall is an essential component of frame house interiors, used for:

• Interior Walls: Standard drywall panels are used to cover wall frames, creating smooth, paintable surfaces in living spaces, bedrooms, and other areas.

• Ceilings: Drywall provides a uniform, finished surface for ceilings, concealing structural elements and wiring.

• Moisture-Prone Areas: Moisture-resistant drywall (often called green board) is used in bathrooms, kitchens, and laundry rooms to prevent mold and water damage.

• Fire Protection: Fire-resistant drywall (Type X) is installed in areas requiring enhanced fire safety, such as around fireplaces or in shared walls of multi-family homes.

• Soundproofing: Soundproof drywall or multiple drywall layers are used in home theaters, bedrooms, or offices to improve acoustic insulation.

Leading Manufacturers of Drywall

Several leading manufacturers produce high-quality drywall products for residential and commercial applications. Key brands include:

1. USG Corporation (USA): Makers of Sheetrock®, offering a wide range of standard, fire-resistant, and moisture-resistant drywall products.

2. National Gypsum (USA): Known for its Gold Bond® products, including lightweight and specialty drywall panels.

3. CertainTeed (USA): Provides a variety of drywall solutions, including noise-reducing and eco-friendly options.

4. Knauf (Germany): A global leader in gypsum products, offering innovative solutions for fire, moisture, and soundproofing.

5. Georgia-Pacific (USA): Known for DensArmor® and DensGlass® moisture-resistant and mold-resistant drywall.

These manufacturers ensure consistent quality and performance, adhering to industry standards and environmental certifications.

Costs and Economic Feasibility

Drywall is an affordable and widely available material, with costs varying based on type, thickness, and performance features. In the U.S., average prices are:

• Standard Drywall (1/2-inch thickness): $10–$20 per 4×8-foot sheet.

• Moisture-Resistant Drywall: $15–$30 per 4×8-foot sheet.

• Fire-Resistant Drywall (Type X): $15–$35 per 4×8-foot sheet.

• Soundproof Drywall: $40–$60 per 4×8-foot sheet.

Labor costs for drywall installation typically range from $1.50 to $3.50 per square foot, including taping, mudding, and sanding. Drywall’s ease of installation makes it an economical choice for interior finishing.

Advantages of Drywall

1. Affordability: Drywall is one of the most cost-effective materials for interior walls and ceilings.

2. Ease of Installation: Lightweight and available in large panels, drywall can be installed quickly, reducing labor costs.

3. Smooth Finish: Drywall creates a seamless, paintable surface ideal for modern interiors.

4. Fire Resistance: Specialized drywall panels provide enhanced fire protection, meeting building code requirements.

5. Soundproofing Options: Acoustic-grade drywall improves sound insulation in critical areas.

6. Versatility: Available in various sizes, thicknesses, and performance grades for different applications.

7. Eco-Friendly Options: Many drywall products are made with recycled materials and are certified for low emissions.

8. Repairable: Minor damage, such as dents or holes, can be easily patched without replacing entire sections.

Disadvantages of Drywall

1. Moisture Sensitivity: Standard drywall is susceptible to water damage and mold growth, requiring moisture-resistant options in wet areas.

2. Fragility: Drywall can crack or dent if exposed to heavy impacts, especially in high-traffic areas.

3. Dust During Installation: Cutting and sanding drywall produces dust that can be messy and harmful if inhaled.

4. Limited Load-Bearing Capacity: Drywall is not suitable for supporting heavy loads without reinforcement or anchors.

5. Time-Consuming Finishing: While installation is quick, finishing (taping, mudding, and sanding) can be labor-intensive to achieve a flawless surface.

6. Not Suitable for Exterior Use: Drywall is designed exclusively for interior applications and cannot withstand outdoor conditions.

Conclusion

Drywall is an indispensable material in frame house construction, providing a cost-effective, versatile, and efficient solution for interior walls and ceilings. Its wide range of types and performance options makes it suitable for various applications, from standard living spaces to moisture-prone areas and fire-rated assemblies.

Although it has some limitations, such as moisture sensitivity and susceptibility to damage, the advantages of drywall far outweigh its drawbacks. For builders and homeowners seeking a reliable and affordable interior finishing material, drywall remains the industry standard and a cornerstone of modern construction practices.