What are HPL Panels?

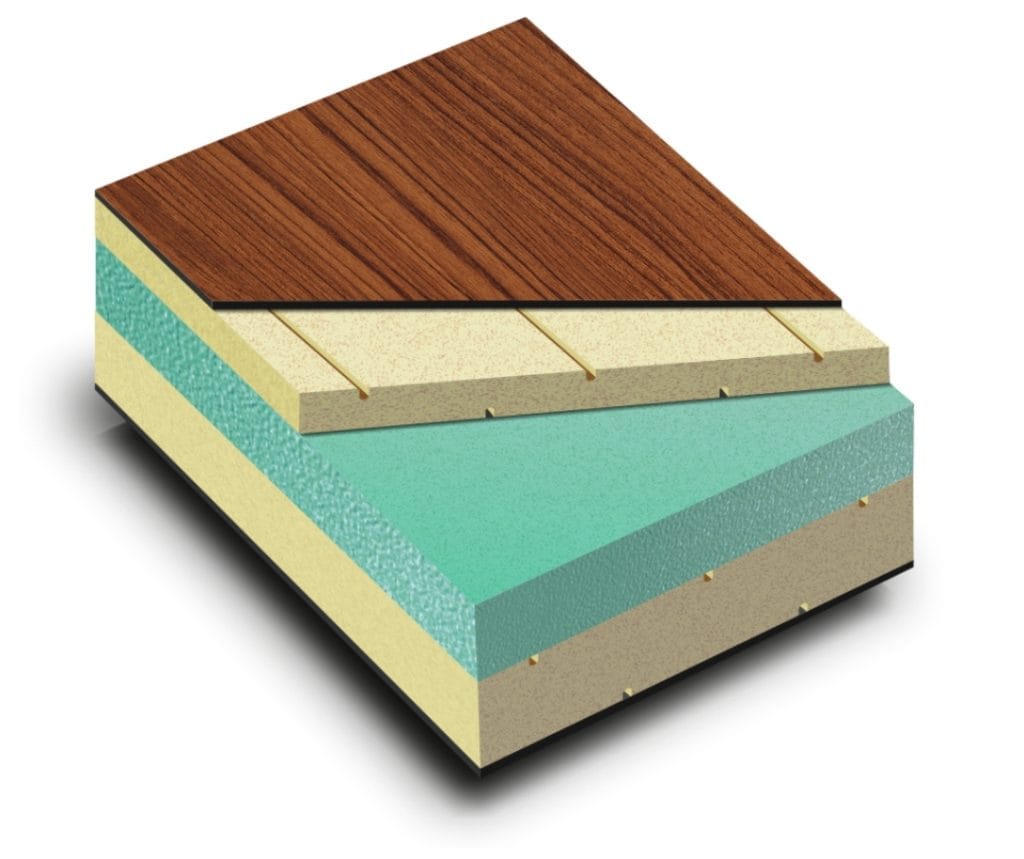

HPL (High-Pressure Laminate) panels are decorative laminated sheets manufactured under high pressure. The material consists of several layers of kraft paper impregnated with thermosetting resins and a decorative layer covered with a protective melamine resin coating. The result is a durable, moisture-resistant, and aesthetically appealing material.

HPL panels have found extensive applications in construction and interior finishing due to their unique properties. They are especially popular in frame house construction, where a combination of lightness, strength, and aesthetics is crucial.

History of HPL Technology and Its Creators

HPL technology originated in the 1920s in the United States. The method of production is attributed to Henry Merrill and Frederick Walton. Initially, the panels were developed for furniture and interior use, but their properties eventually allowed for expansion into exterior applications, including building facades and frame house construction.

Modern advancements in this technology focus on improving the pressing process and introducing new components into the panel structure. Manufacturers worldwide are working to enhance the aesthetic and functional characteristics of HPL panels, making them a key material in contemporary architectural and design solutions.

Applications in Frame House Construction

Frame construction is a method where a lightweight wooden or metal frame serves as the structural core of a house, which is then sheathed with panels. HPL panels are an excellent fit for such structures due to the following advantages:

• Facade Cladding: HPL panels are widely used for creating durable, weather-resistant facades. They protect the structure from external impacts and provide an aesthetically pleasing appearance.

• Interior Walls and Ceilings: Their light weight and ease of installation make these panels ideal for interior use.

• Terraces and Balconies: Thanks to their moisture resistance and ability to withstand temperature fluctuations, HPL panels are suitable for outdoor applications.

Leading HPL Manufacturers

Several companies lead the global market in HPL production. Among the most recognized and reliable manufacturers are:

1. Fundermax (Austria): A leader in producing facade and interior panels, known for high-quality standards and a wide range of textures and colors.

2. Trespa (Netherlands): Specializes in innovative solutions for facades and interior surfaces.

3. Egger (Austria): A manufacturer offering HPL panels alongside other construction and design materials.

4. Abet Laminati (Italy): One of the largest producers of decorative panels, renowned for its attention to design and details.

5. Arpa Industriale (Italy): Produces premium panels with unique textures and aesthetic solutions.

Each of these companies ensures high quality, durability, and environmental sustainability in their products.

Costs and Economic Feasibility

The cost of HPL panels varies depending on the brand, size, thickness, and texture. On average, the price is as follows:

• Interior Panels: $10–$30 per square foot.

• Facade Panels: $30–$60 per square foot.

Installation costs also depend on the complexity of the project and additional components like fasteners. Overall, HPL panels are considered a cost-effective solution due to their longevity and low maintenance requirements.

Advantages of HPL Panels

1. Durability: HPL panels are resistant to mechanical damage, UV radiation, and temperature fluctuations. They maintain their properties and appearance for decades.

2. Moisture Resistance: The material is virtually non-absorbent, making it ideal for use in regions with high humidity or fluctuating climates.

3. Environmental Friendliness: Many manufacturers use recycled materials and environmentally safe resins in production.

4. Aesthetics: A wide variety of textures, colors, and designs allows for the realization of any architectural or design ideas.

5. Ease of Installation: The lightweight panels and their convenient format simplify installation, reducing construction time.

6. Fire Resistance: Most HPL panels have a high fire-resistance rating, enhancing the safety of buildings.

Disadvantages of HPL Panels

1. Cost: While generally affordable, high-quality panels can be more expensive than some other finishing materials.

2. Installation Requirements: Proper installation requires specialized fasteners and skilled professionals, potentially increasing costs.

3. Rigidity: While advantageous for facades, the rigidity of the panels may limit their use in complex architectural designs.

4. Preparation of the Frame: To ensure long service life, it’s essential to carefully prepare the frame or base onto which the panels will be installed.

Conclusion

HPL panels are a modern, practical, and aesthetic solution for frame house construction. Thanks to their durability, moisture resistance, and ease of installation, they are becoming increasingly popular for both exterior and interior applications.

Despite a few drawbacks, their advantages outweigh them, making HPL panels a worthwhile investment in construction. Innovations in production and the growing variety of manufacturers enable architects and builders to create unique projects that meet modern standards.